New Cars for the Chicago Elevated (1926)

Electric Railway Journal · Vol. 67, No. 5 · January 30, 1926 · pp. 182-184.

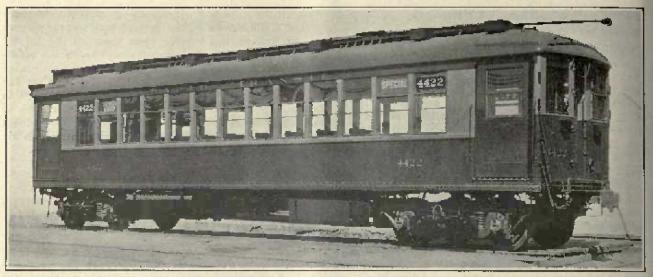

One of the New Cars. Steps Are Unnecessary Because High Level Platforms Are Used at All Stations.

New Cars for the Chicago Elevated. Several Features Are Included to Give Greater Convenience and Comfort, Although the New Equipment Is Practically a Duplicate of that Already in Service.

By Colin K. Lee, General Engineer, Westinghouse Electric & Manufacturing Company.

One hundred new steel cars have been ordered by the Chicago Rapid Transit Company recently to increase the service on its elevated lines. The electrical equipment is virtually a duplicate of that ordered in 1922, and that in turn was practically a duplicate of the 1914 order. An accompanying table gives the principal dimensions of the new cars. Particular attention has, however, been given toward providing a car of pleasing appearance both inside and out.

Seats are provided for 52 passengers. Thirty-six can be accommodated on the cross-seats. Four longitudinal seats, one at each corner of the car, provide for the remaining sixteen passengers. The seats are soft and plush covered. They are a trifle wider than those usually found in city service, being 37 in. wide. The seat spacing is 32J in., which also provides somewhat more knee room than is usually found. The increased width of the seat has narrowed the aisle somewhat, so that this is but 211 in.

Hand straps of a white enamel rigid type are used only at the ends of the car over the longitudinal seats, which are 6 ft. long. Looking through the car from one end, the passenger is impressed particularly with the unobstructed view. There are no vertical stanchions in the line of vision, which usually give a crowded appearance, regardless of their desirability for convenience of standees. The clear vision of the passengers is also extended to the side windows, which are arranged particularly to give an unobstructed view outside with no guard railings. Plate glass gives a rich effect and there is no danger of outside objects presenting a wavy appearance.

Arch-type roofs are used and the line where the roof joins the end partition has a simple graceful curve. Lights are arranged in three rows, one down the center of the car and one row on each side. The lighting fixtures are attractive. Deep translucent shades shield the lamps so that direct rays do not annoy the passengers. Efficient lighting is obtained through the use of the white enameled arch ceiling. The interior finish, aside from ceiling and floor, is mahogany. Twelve ventilators are arranged in the roof. In addition, two 12-in. electric fans are provided, one at each end of the car. These fans are driven from a storage battery.

Particular attention has been given to make the car warm and soundproof. Thick salamander insulation is used, with double wood floors on top of the steel plates. Exposed sheets, such as sides and letter-boards, are of Armco iron. Other details of reconstruction include 12.25-lb. I-beam center sills, 6-in. channel side sills, 3/16-in. pressed cross-sills, 1/16-in. continuous floor plate, 1/16-in. steel headlining and pressed steel side posts and doors.

The motive equipment consists of two Westinghouse No. 567-R-l motors, both mounted on one truck. These motors are a standard Westinghouse type, slightly modified to meet local conditions. Covers and axle caps are chained to the frame as a loose piece is particularly undesirable in elevated car operation. Other important features of this ventilated motor include through axle cap bolts, bolted commutator, dust guards, axle shields, tapped field, pressed steel gear case, etc. Strap windings are used without sharp crossovers. The control is type ABLFM, which includes automatic acceleration, energy control supplied either from battery or direct from the line and field control for the motors. It is arranged for operation in conjunction with existing elevated equipment, which includes General Electric type M.

The motorman's compartment occupies the front right-hand side of the platform at each end of the car. This is inclosed by a door which stands lengthwise of the car when occupied by the motorman. When not in use the door swings forward and incloses the motorman's control devices. The control equipment must thus be capable of installation in a comparatively narrow space. The master controller is type XM-110. It is provided with three drums, placed one above the other, with three concentric operating shafts. The reverse handle is arranged so that it cannot be left when the motorman leaves his post.

A new feature is the arrangement of the switchboard equipment. A full length steel cabinet is built into the platform face of the bulkhead at the left side of the platform. This contains the panel bearing, three heater switches, switches for lights and air compressor and the large knife switches for trolley and third rail, heat and light bus, main motors, air-door-switch cut-outs, together with the necessary fuses. Each item is marked plainly, and in spite of the large number of devices the space occupied is surprisingly small.

Principal Dimensions and Equipment of Chicago Rapid Transit Cars

- Number ordered: 100

- Builder: Cincinnati Car Co.

- Seating capacity: 52

- Length over all: 48 ft. 0 in.

- Length over body: 37 ft. 10 in.

- Length of platform: 5 ft. 1 in.

- Extreme width over eaves: 8 ft. 10 7/16 in.

- Width over side sheathing: 8 ft. 8 15/16 in.

- Rail to bottom of side sill: 3 ft. 2 in.

- Rail to top of roof: 12 ft. 3-1/4 in.

- Width cross-seats: 37 in.

- Width of aisle: 21-3/4 in.

- Length of longitudinal seats: 6 ft. 0 in.

- Sliding side door opening: 3 ft. 8 in.

- End door opening: 22-1/2 in.

- Truck centers: 33 ft. 8 in.

- Wheelbase motor truck: 6 ft. 6 in.

- Wheelbase trailer truck: 5 ft. 6 in.

- Diameter wheels motor truck: 34 in.

- Diameter wheels trailer truck: 31 in.

- Height rail to center of drawbar: 29-1/2 in.

- Post centers: 2 ft. 7-7/8 in.

- Weight complete: 76,400 lb.

- Body: Steel

- Interior trim: Mahogany

- Roof: Arch

- Air brakes: Westinghouse type AMU

- Control: Westinghouse ABLFM

- Couplers: Sterns & Ward automatic; Van Dorn automatic

- Door-operating mechanism: National Pneumatic

- Heaters: Consolidated Car Heating Co.

- Motors: Two Westinghouse 667-R-l, 170 hp. at 600 volts

- Seating material: Plush

- Trucks: Baldwin Class 66-30-AT, Special, and Baldwin Class 78-30-A, Special

- Ventilators: Railway Utility Co.

- Wheels: Driving truck, 34 in. ; trailer truck, 31 in.

|

| Floor Plan and Seating Arrangement of the New Cars. |

|

| [Left] Seats Are Wide and Plush-Covered. Lighting Is Good and Passengers Are Afforded an Unobstructed Vision. [Right] Short Longitudinal Seats at the Doorways Help to Prevent Congestion by Providing a Wide Aisle at Ends. |

|

| At Left- Motorman's Compartment Is Located at the Front Right-Hand Side of the Car. When Not In Use It Is Made a Part of the Vestibule by Closing the Door to Conceal the Operating Equipment. At Right The Switch Panel Is a Completely Inclosed Unit on the Platform. |

Sources

Electric Railway Journal, McGraw Hill Company, Digitized by Microsoft, Americana Collection, archive.org.